This is the multi-page printable view of this section. Click here to print.

Integrated VTI (iVTI)

- 1: Overview of the iVTI Operation

- 2: Getting Started with the iVTI

- 3: Operating the iVTI

- 4: Troubleshooting iVTI Operation

1 - Overview of the iVTI Operation

iVTI - How it Works

The integrated Variable Temperature Insert (iVTI) is a liquid cryogen-free (dry) cryostat built into the superconducting magnet of the EPR spectrometer. It operates by circulating helium gas around a closed-loop circuit cooled by the same cryocooler that is used to cool the superconducting magnet coil. The iVTI can operate continuously and in conjunction with the magnet.

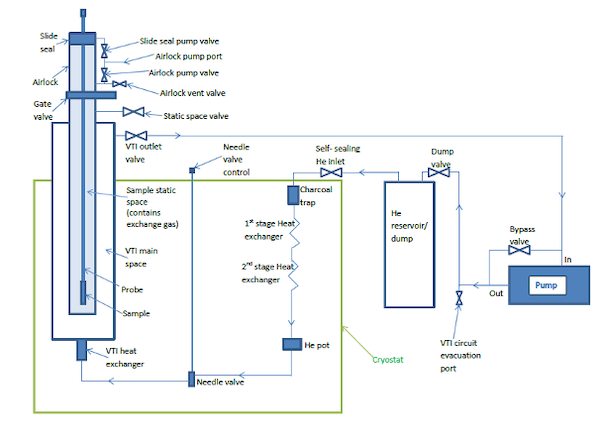

Schematic of the iVTI

A schematic of the iVTI is shown above. High quality helium gas (grade 5) is stored at room temperature in the helium reservoir and a dry (oil-free) pump drives drives the circulation of the helium gas through a closed cycle circuit. Under normal operations, the bypass valve (V16) is closed and the helium reservoir valve (V12) and iVTI outlet valve (V11) is open. The helium gas passes from the helium reservoir and into the iVTI circuit via the self-sealing helium gas inlet.

Once the helium gas enters the magnet space, it first passes through a charcoal filter to remove any impurities within the gas. It then flows through the first stage heat exchanger which cools the gas to ~40K. The gas then passes to the second stage heat exchanger where it is cooled further to below 4.2K and condenses in the helium pot. The helium pot has an integrated heater to keep the pot at a recommended temperature of 3.1 K.

To cool the cryostat space, the liquid helium then flows across the needle valve, at which point it expands and cools further to approximately 1.6K. The cooled gas/liquid mixture then passes through the iVTI heat exchanger where the helium is heated to the required temperature. The helium gas flows upwards in an annular space surrounding the static column (containing the EPR probe) to the top of the iVTI where it exits and is circulated through the pump and exhausts back to the dump vessel.

The probe is cooled using an exchange gas, which is cooled at the wall of the static column.

The temperature inside the cryostat is regulated using the iVTI heater located at the bottom of the static column, and the heating power is regulated by the temperature controller. To achieve the most accurate temperature at the position of the sample, all Bridge12 EPR probes are equipped with a calibrated Cernox temperature sensor. This sensor is located as close to the sample as possible for accurate temperature readings and this temperature is used to control the heater power in a feedback loop.

If the probe is removed from the cryostat, the temperature can be regulated using the internal iVTI temperature sensor. Note, that the iVTI temperature is not necessarily equal to the sample temperature.

Integrated Heaters

The magnet system with integrated VTI has in total three internal heaters that are all connected to the temperature controller (typically a LakeShore Model 350). The following table summarizes the function of the heater and gives some default operation parameters.

| Heater | Description |

|---|---|

| Heater 1 (VTI) | The VTI heater is used to regulate the cryostat temperature. Typically, the heater control loop is connected to one of the temperature sensors (this is done in the settings for the temperature controller). For the Q-Band spectrometer the user has the option to control the cryostat temperature using the temperature sensor of the VTI or the one integrated into the EPR probe. Bridge12 recommends using the temperature sensor of the EPR probe for accurate temperature readings. |

| Heater 2 | Not used |

| Heater 3 (Helium Pot) | During operation some the helium of the VTI used for cooling is condensed inside the helium pot and the flow of helium is controlled by the needle valve (see figure above). Under normal conditions, the temperature of the helium pot should be kept at around 3.3 K. To achieve this temperature the heater output power should be set to a value of about 5 to 10 % (open loop) to maintain that temperature. This value only needs to be changed if the user wants to go to very low temperatures (e.g. < 5 K) and the user should first read the instructions in the manual to set the temperature of the helium pot. |

| Heater 4 (Charcoal Trap) | During normal VTI operations the helium passes through an activated charcoal filter to remove any residues (oxygen, nitrogen, etc.) from the helium gas used for cooling. After a while this charcoal filter needs to be degassed (cleaned) using the charcoal heater. This is a low power heater and the heater can be ramped up to 100%. While ramping up the heater, please monitor the temperature of the charcoal trap in the logging system. During normal operations, the charcoal heater is off. |

2 - Getting Started with the iVTI

Important

Before operating the iVTI please familiarize yourself with the principle of operations described in the section iVTI Overview.

The following section provides information about day-to-day operation of the cryostat. If you need assistance troubleshooting iVTI operations, please first consult the manual or contact Bridge12 or CRYOGENIC.

Prior Checks Before Operating the iVTI

Warning

Do not use excessive force or overtighten the needle valve as this can lead to permanent damages of the valve.

Note

If the needle valve is closed and open again, a faint clicking sound is heard as the needle pulls away from the needle valve seat.

Once the magnet has achieved its base temperature the following checks should be performed prior to operating the iVTI:

- Make sure the dry pump bypass valve (V16) is closed.

- Make sure the helium reservoir valve (V12) and the iVTI outlet valve (V11) are open.

- Start the dry pump and adjust the needle valve to a pressure of approximately 5-8 mbar at the head of the iVTI. Please note the needle valve may require several further adjustments as the temperature profile within the flow circuit varies whilst steady-state flow conditions are established in the circuit.

Within a short period of time, the cryostat should reach its base temperature of ~ 1.8 K.

Setting an optimum flow rate requires some experience from the user. The factors that must be considered are:

- If the flow rate is too low the 2 K base temperature of the iVTI may not be achievable, as the available cooling power of the gas may be too low.

- If the flow rate is too high the cryocooler second stage temperature will rise which may affect the maximum ramp rate of the magnet.

- If the flow rate is too high the cryocooler may not condense at a fast enough rate. This leads to rapid boiling of the condensed gas in the circuit and a rapid pressure rise of the circuit.

Typically the iVTI can operate with a single needle valve setting over its whole temperature range. However, if a rapid cooldown is required the user can increase the flow and then subsequently re-adjust the needle valve to give a lower flow setting once the iVTI has cooled close to the required temperature.

3 - Operating the iVTI

Important

Before operating the iVTI please familiarize yourself with the principle of operations described in the section iVTI Overview.

The following section provides information about day-to-day operation of the cryostat. If you need assistance troubleshooting iVTI operations, please first consult the manual or contact Bridge12 or CRYOGENIC.

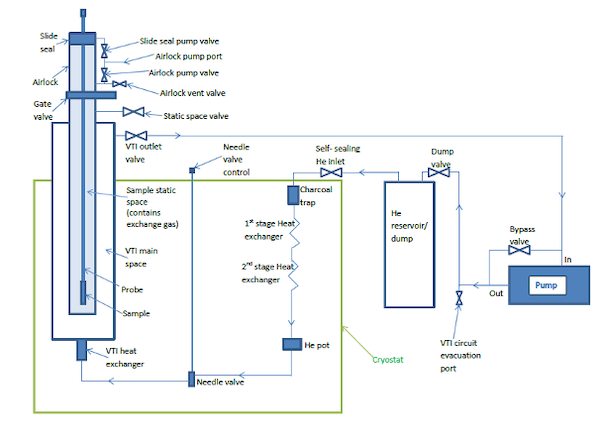

Schematic of the iVTI

The iVTI operates by circulating helium gas in a closed-loop circuit. A schematic of the circuit is shown above. The following instructions assume the magnet is at its base temperature and the iVTI has passed operational checks.

Cooldown of the iVTI

To cooldown the cryostat follow these instructions:

- Make sure the dry pump bypass valve (V16) is closed.

- Make sure the helium reservoir valve (V12) and the iVTI outlet valve (V11) are open.

- Start the dry pump and adjust the needle valve to a pressure of approximately 5-8 mbar at the head of the iVTI. Please note the needle valve may require several further adjustments as the temperature profile within the flow circuit varies whilst steady-state flow conditions are established in the circuit.

While the cryostat cools down, the pressure of the helium reservoir will decrease as more helium condenses in the helium pot.

Setting the Cryostat Temperature and Regulating the Helium Flow

Setting the Temperature

The temperature at the position of the sample is set at the temperature controller. This can be done either manually at the front panel of the temperature controller or through the spectrometer control software SpecMan4EPR. Under normal operations, when there is an EPR probe installed, the temperature of the cryostat is regulated based on the probe temperature sensor readings to give the most accurate control over the temperature at the position of the sample. Once the temperature is set, either on the front panel or through SpecMan4EPR, the user needs to adjust the helium flow by adjusting the needle valve. However, once the desired temperature is reached, no further optimization is required.

Optimization of the temperature controller PID and heater range parameters is beneficial if the ultimate system performance is to be achieved. The parameters may vary depending upon the flow rate established in the circuit. Typical starting values for the PID settings are 250,120,30 which will provide reasonable control over the whole temperature range. However, the user is encouraged to adjust PID settings to further optimize the system as an experience of the iVTI is established. The heat exchanger is fitted with a heater (30 Ohm / 30 W). Under no circumstances should a current greater than 1A be applied to the heat exchanger heater, as it will fuse the leads.

Setting the Needle Valve for Optimum Flow Control

The needle valve creates a controllable impedance for the helium circulation. It is set initially and thereafter should need only occasional adjustment. A dial gauge is fitted at the top of the iVTI to allow the user to set and monitor the flow rate (directly related to pressure). A pressure between 5 and 15 mbar at the top of the iVTI is recommended. The optimum value is specific to each system.

Under normal conditions, a pressure of about 10 mbar can cover a wide range of temperatures. Especially, for experiments that are performed at about 50 to 60 K, the position of the needle valve rarely has to be changed.

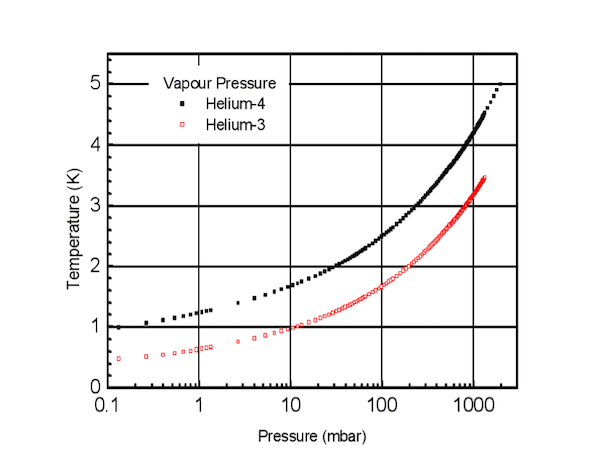

To operate at temperatures below 10 K, the pressure may have to be adjusted using the needle valve. In this case, the optimum value will correspond to the vapour pressure curve as shown in the figure below.

Helium Vapor Pressure

In general, if the helium flow rate is too low there may not be enough cooling power available from the circulating helium and the system may not reach the base temperature of the iVTI. A slightly too high a flow rate and the system will not reach base temperature because it is not following the vapour pressure curve.

However, if the flow rate is far too high the amount of heat that needs to be extracted from the circulating helium will exceed the cooling power of the cryocooler. In this case, the temperature of the cryocooler 2nd stage, magnet and helium pot will increase and the liquefaction of helium in the iVTI circuit will slow or stop. Under these circumstances, the helium pot will eventually empty preventing the iVTI from achieving base temperature. The associated increase in temperature will also affect the magnet ramp rates.

It should be noted that the helium flow is also affected by the impedance of the tubes close to the iVTI heat exchanger. The overall impedance depends on the temperature of the heat exchanger. A higher driving pressure is needed between the helium pot and the iVTI when the iVTI is at a high temperature than when it is at a low temperature. The liquid helium in the helium pot is effectively in equilibrium. So the pressure of the gas above the liquid in the helium pot follows the vapour pressure curve for helium 4 shown in the figure above. Since the inlet circuit has a low impedance, the pressure in the helium reservoir is close to that at the helium pot and can be used as a gauge as to how much helium has been condensed into the pot. A heater on the helium pot is used to control the temperature of the helium pot and hence control the driving pressure. The temperature is set to a recommended value of 3.1 K. The helium pot temperature is controlled via a software PID loop.

Changing the Sample

During the process of changing the sample, the iVTI circuit will continue to run and the dry pump should not be switched off. To change the sample, follow these instructions:

- Removing the Sample

- If you want to insert/replace a new sample, make sure the sample is properly mounted on the sample stick. If you want to remove the sample without inserting a new sample, make sure you have a blind plug handy.

- Make sure the experiment is finished.

- Make sure helium purge gas is available and the pressure regulator is set to the correct value. For the sample exchange circuit, the pressure regulator should be set to a pressure of 3-5 psi.

- Open the valve to the cryostat, located at the top of the magnet and observe the pressure inside the cryostat. You should charge the cryostat space to about 1 psi. A safety valve, located close to the valve will release all excess pressure.

- Loosen the nut securing the sample stick.

- Slowly pull out the sample stick. The sample stick has holes at the top and bottom of the G10 section (green). Once the top hole passes the nut securing the sample stick, cold helium gas will exit the hole. Pull the sample stick out of the probe and properly store the sample. While the purge gas is running, air is prevented to enter the sample space.

- Inserting the Sample

- With the purge gas running, insert the sample stick into the probe.

- Slowly lower the sample stick into the probe. Once the bottom venting holes of the sample stick have past the nut securing the sample stick the helium purge gas will exit at the top holes of the sample stick. Wait for a couple seconds to purge the space inside the of the sample stick.

- Optionally, open the nut at the top of the sample stick to purge the space inside the stainless steel section of the sample stick.

- Slowly push the sample stick into the resonator. At this point, the user should also monitor the resonator tuning in the control software. Once the sample tube is entering the resonator, the frequency will shift to a lower value. Push the sample stick until it is properly seated at the top of the resonator.

- Tighten the nut securing the sample stick. Important, this only needs to be hand-tightened. Do not use any tools to tighten this nut.

- Close the valve to the helium purge gas supply.

- Switch on the diaphragm pump to evacuate the sample space. Lower the pressure to about 200 - 500 mbar. The exact value depends on desired temperature and will require some user experience.

- Close the valve to the iVTI located at the top of the magnet.

- Turn off the diaphragm pump.

Once the sample is loaded into the resonator make sure to close all valves to the helium supply for purging.

4 - Troubleshooting iVTI Operation

Important

Before operating the iVTI please familiarize yourself with the principle of operations described in the section iVTI Overview.

The following section provides information about day-to-day operation of the cryostat. If you need assistance troubleshooting iVTI operations, please first consult the manual or contact Bridge12 or CRYOGENIC.

Blockage in the iVTI Circuit

The most likely cause of abnormal iVTI performance is a blockage in the iVTI circuit due to ingress of air.

Symptoms of a iVTI partial blockage before the helium pot can include:

- Reduced flow at a given needle valve setting.

- Reduced pressure at the iVTI pumping side for a given needle valve aperture.

- Increased pressure at the external helium reservoir.

- Decreased temperature of the 2nd stage and helium pot.

The pressure in the helium reservoir increases as the partial blockage limits the flow of helium through the inlet heat exchangers. The 2nd stage and helium pot temperatures may fall as the cryocooler heat load is reduced due to the lower helium flow rate at the 2nd stage.

Symptoms of a blockage after the helium pot are similar; however, in this case, the helium reservoir pressure may fall as the helium charge is condensed into the system with a reduced flow returning to the reservoir.

If a blockage is suspected the following actions are recommended:

- Heat the iVTI to room temperature. In some cases, this may clear the blockage.

If the blockage persists, please follow these steps:

- Once the iVTI is at room temperature, disconnect the helium reservoir hose at the face-sealing connector on the cryostat.

- Connect an external pump to the face-sealing connector of the cryostat using the fitting that was provided with the system. This connection provides the most efficient pumping of the inlet circuit which is the most likely location for any blockage to occur.

- Close the valve at the head of the iVTI (V11) to the dry pump and open the needle valve fully.

- Pump the iVTI via the external pump and switch off the compressor.

- Heat the charcoal trap using the temperature controller and maintain it at 300 K.

- Wait for the 2nd stage to rise in temperature above 90 K.

- Turn off the charcoal heater, isolate the external pump and restart normal flow through the iVTI circuit.

If the blockage persists, continue to warm the system to room temperature and replace the helium of the iVTI circuit as outlined below.

Replacing the Helium in the iVTI Circuit

If contamination or loss of helium in the iVTI circuit is suspected please follow these instructions to replace the helium charge:

- Make sure the system is at room temperature and the dry pump is not running.

- Connect a T-connector to the plug valve on the exhaust side of the dry pump. One arm of the T should be connected to a clean helium source with an in-line valve, and the other to a pump via a valve. The helium source should be either a bottle of high purity gas (99.95%, grade 5) or the boil-off gas from a helium storage vessel. Do not use standard (balloon) grade bottled helium for this purpose as this can have a high moisture content.

- Open the connection to the external pump and pump out the helium reservoir. Once the pressure is low enough (< 1e-3 mbar>) activate the dry pump and use it to purge the internal iVTI circuit.

- Close the valve to the external pump and fill the reservoir to a pressure of +1psi above atmospheric pressure with pure helium gas.

The system is now ready for cooldown and operation.